PRODUCT DESCRIPTION

The compact series consists of two types of temperature measuring instruments which are compact and complete in themselves, providing:

- temperature measurement

- display of the measured values

- alarm messages

- remote indication of the measured values

An extra advantage is that the temperature sensors are quite small and fit in all standard transformer thermometer pockets and wells.

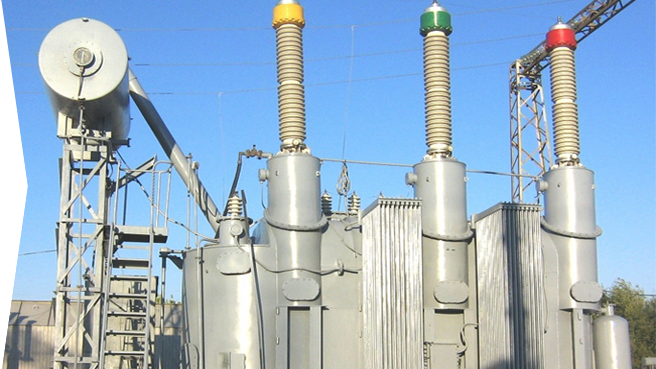

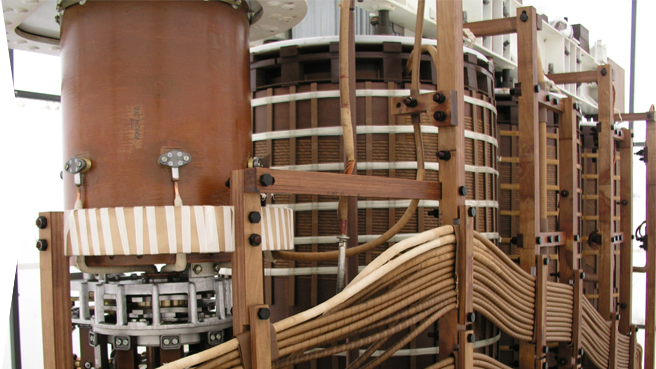

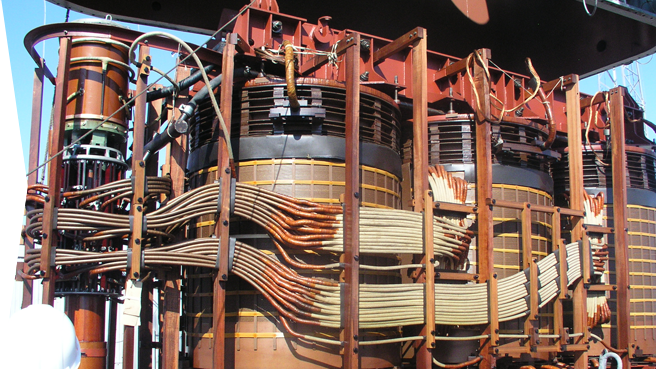

The temperature of the winding is measured and determined indirectly. The temperature difference between the winding and the coolant is a function of the actual current in the winding. The transformer secondary current is proportional to the current in the transformer winding. The secondary current of the transformer feeds a heating resistor in the thermometer and so produces a display reading of the transformer load, corresponding to the actual measured oil temperature(temperature gradient). This indirect method provides a display of the average or maximum winding temperature(i.e.a thermal image). The heater current is set to a characteristic curve using a potentiometer located in the dial indicating thermometer. It can be set in the factory or by the customer.

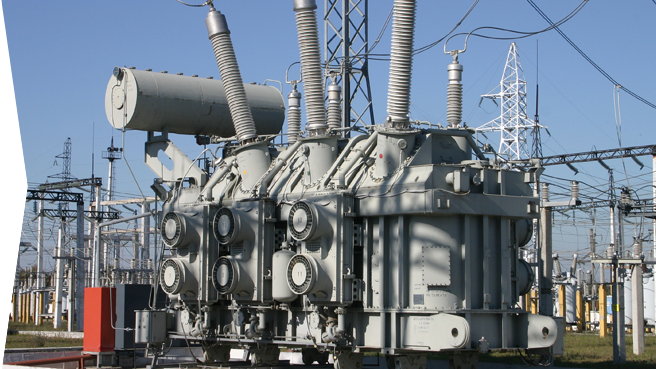

Dial indicating thermometers with adjustable microswitches. The mechanical measuring system is autonomous, energy independent and remains serviceable and stable long-term. The dial indicating thermometer is installed in the thermometer pocket in the transformer tank and provides a direct indication of the measured value.

The thermometers are suited for application in extreme climate conditions; through the UV laminated safety glass measuring values can be read even after decades. The closed system with pressure cell keeps dirt and water out. So there isnoreadjustment or re-calibration necessary for the entire lifetime.

You can combine the following devices with the compact series:

- Signal Converter TT30to convert the sensor signals in analogue (for instance 4....20mA) or digital (RS485) process signals

- Signal Converter IgT-MUto shape and isolate a direct current to form an injected direct current and/or a DC voltage signal

- Electronic Indicator El100/160for temperature indication in the switchboard / switching cubicle

- Digital Indication D1270 /1272

- Moving Coil Indicator PQ96 /PQ144for remote indication

- Multi Ballast Transformerto adapt the current transformer output to the input of the pointer thermometer