Вот уже более 85-ти лет компания MR производит устройства РПН для регулируемых трансформаторов. MR остается ориентиром для производителей оборудования в этой отрасли. Хороший пример тому - новая вакуумная технология.

The VACUTAP® series, just one example, with its vacuum switching technology for on-load tap-changers in oil-immersed and dry-type transformers. This is now the most common form of technology in reactor-type tap-changers and has revolutionised resistor-type tap-changers. We have been using this technology since the 1980´s and are continuously refining it thus bringing you advantages such as no service requirements before 150,000 to 500,000 switching operations, drastically reduced running costs for the whole physical life, increased availability of the transformer, no oil carbonization, no replacement of contacts and no oil filter systems - to mention but a few of the many benefits.

To a great extent the OILTAP® - program with its conventional tap-changer technology (arcing contacts in oil) and already well-known to you, is still available as an alternative.

Solutions for replacement of the Bulgarian tap-changers types RS-3, 4, 9

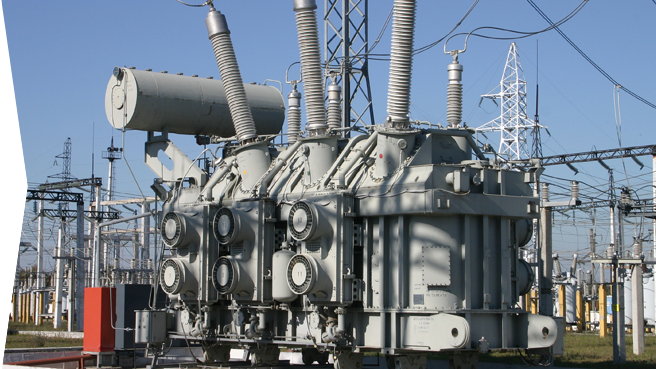

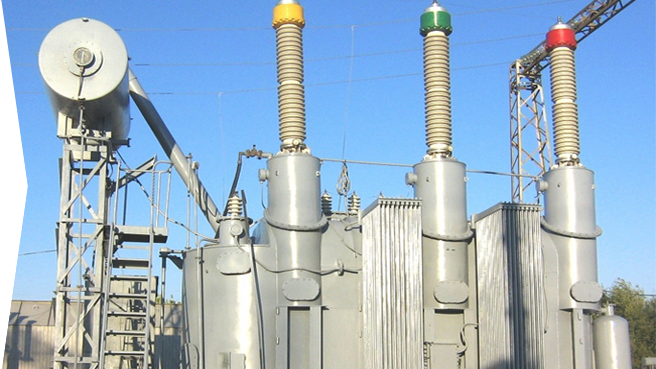

Many electric utilities and industrial plants in the former Council for Mutual Economic Assistance (CMEA) for many years used the tap changer made in Bulgaria. Currently, most of these devices have already worked out their operating life. However, along with this, many transformers, which were set tap-changers produced in Bulgaria, are still in working condition and installation of the new tap-changer, replace the outdated, will significantly extend the life of these transformers.

Asiaremenergo offers professional and convenient solution for the replacement of tap changer:

Instead of the standard type switch RS, produced in Bulgaria, we propose a switch type OILTAP® MSE produced by MR, Germany.

Benefits of replacing old tap-changer on the MR tap-changer:

High quality

Reliability

Motor-driven equipment newly developed type TAPMOTION® ED

Replacement procedure does not require major alterations

Replacement for 1 day

Easy to service

Long service intervals

Professional service and support

Description of the installation process:

Disabling the transformer, grounding, blocking possible inclusion, oil drain opening hatch

Disconnecting and labeling of taps

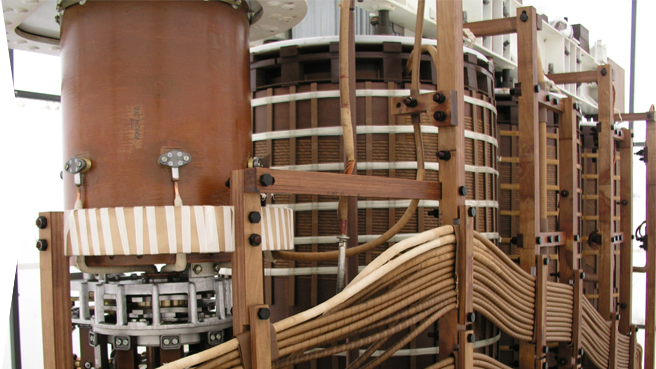

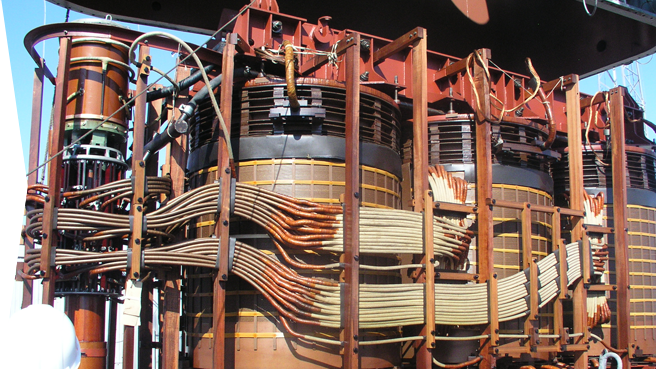

Extract from the old tank the tap changer

Installation of new OLTC type MSE

Adaptation and connection taps to the tap-changer

Mounting the motor drive, the mechanical coupling, bevel gear and protective relay

Measurement of the transformation ratio, drying and oil filling, testing